- Wire Mesh Fence Series

- QYM - Fence Special For Park

- QYM - Sport Ground Fence

- QYM - Services Fence

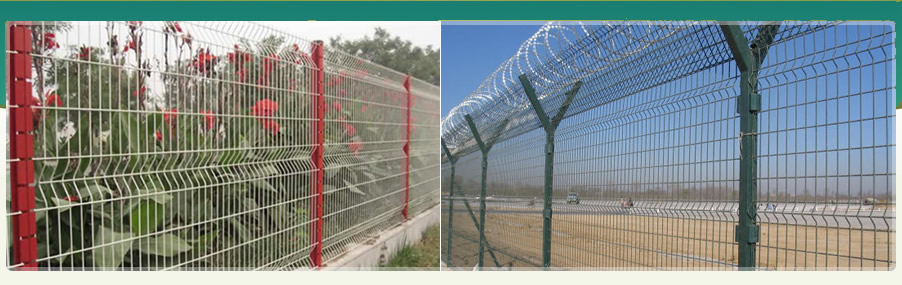

- QYM - Fence Special For Airport

- QYM - Europe Style Fence

- QYM - Border Security

- QYM - Highway Protection Fencing

- QYM - Railway Protection Fencing

- QYM - Security Wire

- QYM - High security fence

- QYM - Double wire fence

- QYM - Temporary fence

- Wire Mesh Series

- QYM - Dust suppression& windproof screen

- QYM - Welded Wire Mesh

- QYM - Hexagonal Wire Netting

- QYM - Expanded Metal Mesh

- QYM - Perforated Metal Mesh

- QYM - Crimped Wire Mesh

- QYM - Bar Grating

- QYM - Stainless Steel Wire Mesh

- QYM - Brass Wire Mesh

- QYM - Insect Screening

- QYM - Black Wire Cloth

- QYM - Square Wire Mesh

- QYM - Galvanized Wire

- QYM - PVC Coated Wire

- QYM - Black Annealed Wire

- QYM - Common Iron Nails

- QYM - Corrugated Nails

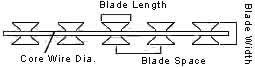

SECURITY WIRE

Originally barbed wire fulfilled the roll of perimeter security.Because it is simple and lower cost. As crime has escalated barbed wire became less and less effective. Petty thefts worsened and the need arose to replace barbed wire with a more effective alternative. The breakthrough came when a barbed fashioned tape was added to a high tensile wire. This product was given the name razor wire! The original product had short blades which were substantially more effective than the barbed wire product.Xinan pioneered the way forward from this point on. Their first upgrade was from short blade to medium blade. Medium blade razor wire had a much sharper edge and quickly gained the reputation of being an extremely effective low cost security product.

Now please note our two series of security wire protuct as follows:

Razor wire series

When you need to get serious about security, Razor Wire is the answer. It is relatively inexpensive, but viciously effective. Razor Wire around the perimeter is enough to deter any would be vandal, robber or saboteur. Razor Wire is made from a corrosion resistant galvanized steel cutting ribbon wrapped around a core of galvanized spring steel wire.

It's impossible to cut without highly specialized tools, and even then it's a slow, dangerous job. Razor Wire is a long lasting and very effective barrier technology, known and trusted by security professionals.

|

|

|

|

|

|

Reference Number |

Blade Style |

Thickness |

Wire Dia |

Barb |

Barb |

Barb |

BTO-12 |

|

0.5±0.05 |

2.5±0.1 |

12±1 |

15±1 |

26±1 |

BTO-15 |

|

0.5±0.05 |

2.5±0.1 |

15±1 |

15±1 |

33±1 |

BTO-22 |

|

0.5±0.05 |

2.5±0.1 |

22±1 |

15±1 |

34±1 |

BTO-30 |

|

0.5±0.05 |

2.5±0.1 |

30±1 |

18±1 |

45±1 |

CBT-25 |

0.5±0.05 |

2.5±0.1 |

25±1 |

16±1 |

40±1 |

|

CBT-60 |

|

0.6±0.05 |

2.5±0.1 |

60±2 |

32±1 |

100±2 |

CBT-65 |

|

0.6±0.05 |

2.5±0.1 |

65±2 |

21±1 |

100±2 |

Barbed wire series

Wire to be made into barbed wire is usually galvanized (coated with zinc) to protect it from corrosion. The wire must be perfectly clean and dry to be properly galvanized. First it is cleaned in a bath of hot, dilute hydrochloric acid, then rinsed with hot water. It then passes through a solution of hot zinc chloride or ammonium chloride to prevent rust from forming as it is dried. After drying, the wire passes through a bath of molten zinc. Excess zinc is wiped off and the coated wire is allowed to cool. (Some-times the wire is coated with aluminum instead in a similar way.) Wire can also be coated with zinc by a process known as electrogalvanizing. The wire is given a negative electric charge and passed through a solution of zinc sulfate or some other zinc salt. The positive zinc ions are attracted to the negative wire and form a coating.

|

|

|

|

|

|

Specifications of Barbed Wire |

||||

Gauge of |

Approximate Length per kilogram in Meter |

|||

Barbs Spacing 3" |

Barbs Spacing 4" |

Barbs Spacing 5" |

Barbs Spacing 6" |

|

12x12 |

6.0617 |

6.7590 |

7.2700 |

7.6376 |

12x14 |

7.3335 |

7.9051 |

8.3015 |

8.5741 |

12-1/2x12-1/2 |

6.9223 |

7.7190 |

8.3022 |

8.7221 |

12-1/2x14 |

8.1096 |

8.814 |

9.2242 |

9.5620 |

13x13 |

7.9808 |

8.899 |

9.5721 |

10.0553 |

13x14 |

8.8448 |

9.6899 |

10.2923 |

10.7146 |

13-1/2x14 |

9.6079 |

10.6134 |

11.4705 |

11.8553 |

14x14 |

10.4569 |

11.6590 |

12.5423 |

13.1752 |

14-1/2x14-1/2 |

11.9875 |

13.3671 |

14.3781 |

15.1034 |

15x15 |

13.8927 |

15.4942 |

16.6666 |

17.5070 |

15-1/2x15-1/2 |

15.3491 |

17.1144 |

18.4060 |

19.3386 |